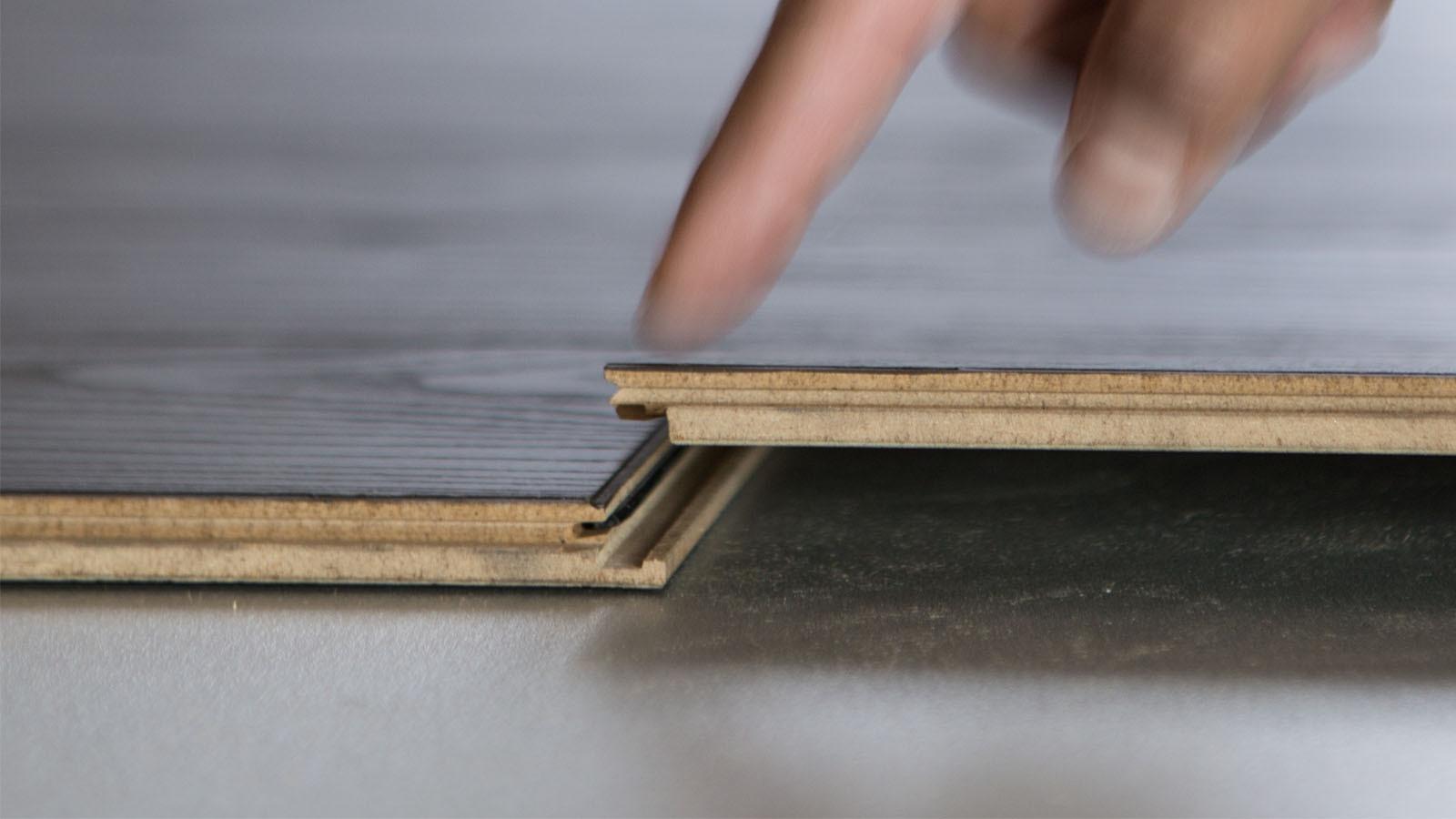

Easy installation with click floorings

The click joints automatically aligns the floor, ensuring every floorboard is straight. You could say that the flooring installer is a built in feature in this system. Should something be wrong, an incorrectly installed floorboard could easily be removed and reapplied to correct the error.

Click floorings leave no gap between the boards

Click floors effectively neutralizes any tensions and stresses that appears in a floor that shrinks and swells with seasonal changes. Therefore you do not need to accept any gaps between the floorboards, which can occur in a glued down floor.

All click floors are not the same

How much a glue-free floor really ”clicks” together depends on the joint system that the manufacturer has chosen to provide the floor with. Some click floors can be installed completely without tools - except from sawing of course - with a simple angling motion and really clicks together. Others have long sides that are angled together but the short sides requires the use of a hammer and a block to merge the two sides. No matter what method is used, the end result is good and the floor will hold together even under great strain.

Real click floors don't have to be hammered to merge

Some manufacturers - usually in the lower price range - market their floors as click floors, although they can not click together at all. Most floors off this type is most a bad imitation of the click floor. Both the long side and the short side must be hammered on both sides to merge, the floorboards can not be detached again to correct errors, the locking system breaks when the floorboards are hammered and it is very difficult to install the floor.